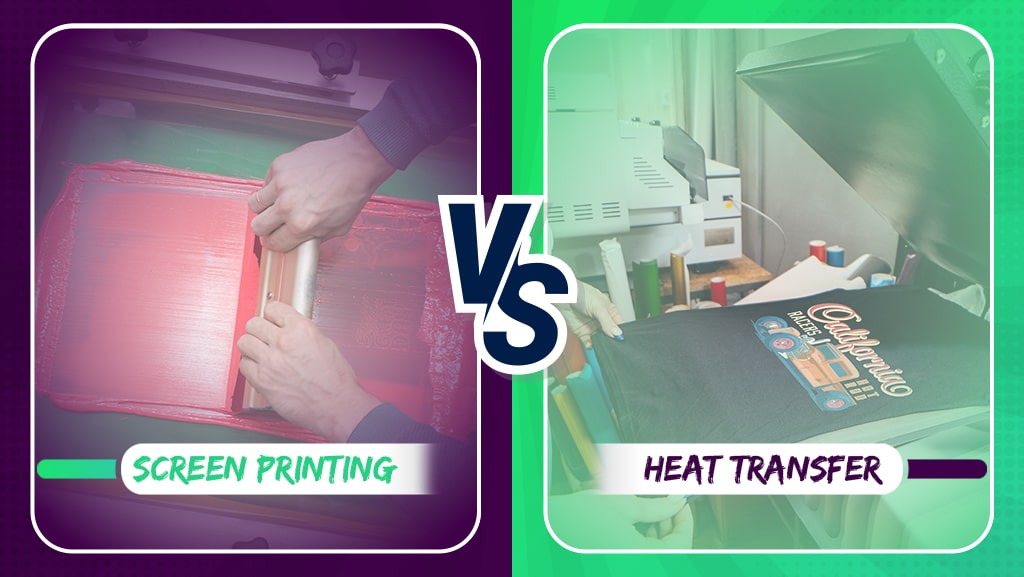

Screen Printing or Heat Press: What should I pick?

Learn the differences between heat transfer and screen printing!

When it comes to printing custom designs on clothing, screen printing and heat transfer are two of the most common methods. Both methods can produce striking results, but they differ in process and durability. With screen printing, ink is forced through a stencil onto fabric, resulting in a durable, long-lasting print that becomes part of the fabric. With heat transfer, a printed design is applied to the fabric with heat and pressure, creating a print that sits on top of the fabric, and can be more prone to fading or peeling.

But what are the pros and cons of heat press vs. screen printing? In this article, we'll review all of that and more.

What is screen printing?

Screen printing is one of the oldest methods of printing shirts; the Chinese first developed the screen printing process in the 10th century! So, how does screen printing work? The process involves a few steps.

First, a silk screen is developed using your design. The area around your design hardens while the area under the design is removed to create a stencil. The screen is then centered on the shirt, pants, or other garments, and a squeegee is used to pass ink over the screen. The ink runs through the area created by your design and into the fabric, and is then dried to cure the ink.

An individual screen has to be used for each color, and it can be complicated to screen print designs with three or more colors. The screen printing process involves a lot of setup, as you have to produce a screen for each color, but the process becomes very efficient once the screens have been created. With screen printing, inks are soaked into the fabric of the garment, which means screen-printed designs have outstanding durability. However, it can be harder to achieve photo-realistic resolution with screen printing than with other printing forms, like heat transfer.

Screen Printing Pros and Cons

Pros

-

Bright, vibrant colors

-

Cost-effective for large orders

-

Creates long-lasting, durable print

-

Absorbs into the fabric for a soft finish

Cons

-

The set up process means more expensive for small orders

-

Not suitable for designs with more than a few colors

-

Lower resolution than heat transfer printing

What is heat transfer printing?

The other most popular method to print clothing designs is heat transfer. The heat transfer process involves using heat and pressure to transfer your design onto the fabric from a special piece of paper.

The two most common types of heat transfer are heat transfer vinyl (HTV) and digital heat transfer. HTV printing is the more traditional method of heat transfer. With this method, logos and letters are printed on a piece of vinyl paper, which has its edges trimmed and is placed on the garment. A heat press is applied to the paper, using tremendous heat and pressure. That transfers the vinyl pieces onto the fabric. With digital heat transfers, your entire design is printed onto a specially made transfer paper, which then transfers the whole design in one heat press.

Heat transfer allows for much more complicated designs, especially when using a digital heat transfer. However, HTV printing creates less durable designs than screen printing because the design is printed on top of the fabric rather than soaked into it.

Heat Transfer Pros and Cons

Pros

-

Cost-effective for smaller orders

-

High-resolution prints

-

Can print designs with many different colors

-

Better for printing in tight spaces like breast pockets or hats

Cons

-

Less durable prints, more likely to crack and fade with washing

-

Not cost-effective for larger orders

-

Heat transfer creates a stiffer feeling shirt than screen printing

Silk Screen vs. Heat Transfer: Which is better?

At this point, we've reviewed the relevant details between silk screen printing and heat transfer for printing fabrics. So, who comes out on top in the heat transfer printing vs. screen printing match up?

The short answer is: it depends on your order. As we've discussed, the initial setup required for screen printing makes it more expensive than heat transfer at smaller quantities. However, once screens have been produced, screen printing is a much faster process than heat transfer, meaning screen printing is the more cost-effective option for larger quantities. Additionally, it's important to consider what you're printing. If you're looking for a photo-realistic print, or if your desired design has more than three colors, a digital heat transfer print is your best bet. However, for a design that won't fade and is soft to the touch, you'll want a screen print.

To decide between screen printing or heat transfer printing, you should consider your budget, the number of shirts you need, the complexity of your design, and the resolution and durability you want for the design. Generally speaking, screen printing is better for larger orders with simpler designs, and heat transfer is better for smaller orders with complex designs or multiple colors.

Frequently Asked Questions

Q: Heat press vs. silk screen: which lasts longer?

A: Screen printing will last longer than heat transfer because the ink is soaked into the fabric, whereas heat transfer prints on top of the fabric. Some fabrics, like polyester and spandex, are difficult to screen print, so heat transfer or sublimation can be better printing options.

Q: Silkscreen vs. heat transfer: what's cheaper?

A: It depends on the quantity of your order. For smaller orders, heat transfer is generally the cheaper option. For bulk orders, screen printing is more reasonable.

Q: How can I get more details about heat transfer and screen printing?

A: For any questions regarding custom printing clothing or other products, call 1-(888) 244-5152 to speak with one of Logotech's product experts, or use our website's chat function.